Vacuum Formed Trays:

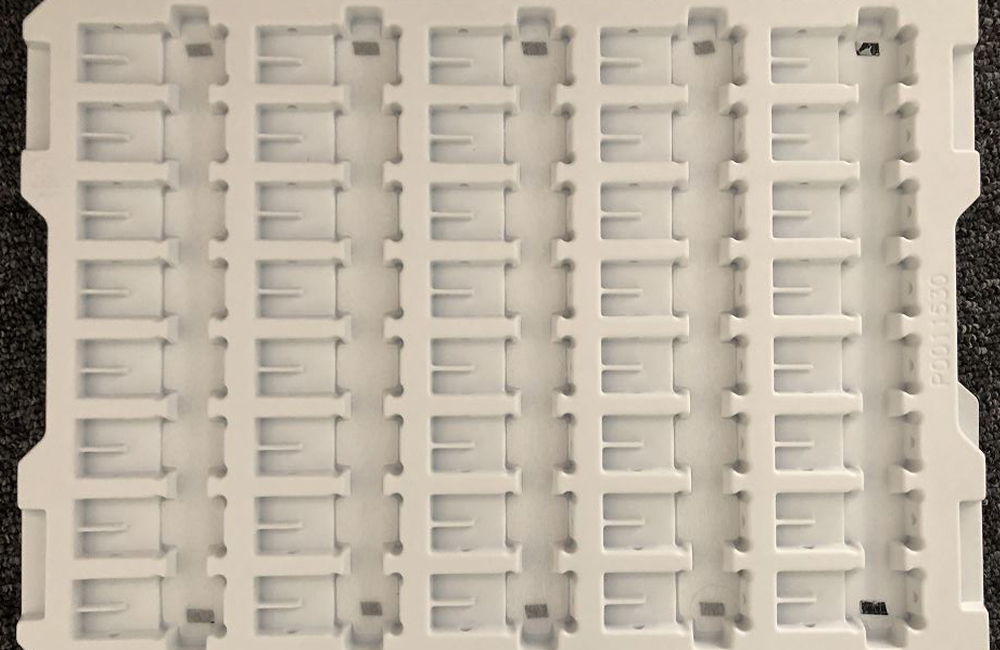

From food packaging to life-saving medical devices, vacuum-formed trays have reshaped our manufacturing processes. Vacuum forming is a manufacturing method used to shape plastic materials. It is a twin sheet forming method that works by heating up plastic and using suction to mold it to the shape of a particular object. This process results in a custom fit to ensure your packaging is secure.

Ameripak designs and manufactures vacuum and thermoformed plastic trays, clamshells, and blister packs. During our thermoforming process, we use heat, vacuum suction, and pressure forming for aluminum production molds as well as various wood species for prototype molds to design the custom trays in the desired shape.

To find out more, request a quote, or place your custom order, contact us today!

Options, Tooling & Customization

Vacuum forming is suitable for a wide variety of packaging applications like cosmetics packaging, food packaging, toys, dental and medical devices, electronics, appliance parts, and more. When you collaborate with our talented in-house design department to house products snugly and securely during material handling, transport, and display, you'll receive custom vacuum-formed trays in your desired material, tray size, and material thickness.

Thermoformed and vacuum-formed trays offer protection during shipment while properly displaying your product. Each tray can be custom-made to fit any size, thickness, and color, and can be constructed from various materials such as:

- High Density Polyethylene (HDPE)

- ABS, High Impact Polystyrene (HIPS)

- Recycled Polyester (RPET)

- Thermoplastic Polyester (PETG)

- Styrene

*Most materials are available with ESD/anti-static coating. The volume and complexity of the design will determine tooling material selection.

Benefits of Vacuum Formed Trays:

No matter what your particular product or application may be, Ameripak is here to create the solutions you need with custom protective packaging you can trust. Our trays are custom-designed using the right material to meet a variety of specialty needs.

We work with you to understand your needs and reduce packaging costs. Our goal is to include as many individual parts per design so that we can reduce end cost to the customer.

Benefits of vacuum-formed trays include:

- Low cost per unit

- Light weight

- Stackable

- Various material options

- ESD/Anti-Static Option

- Perfect to WIP

- Cavity count can be customized

- Securely nests in tight shipping boxes

To learn more about Ameripak's vacuum forming capabilities and how they can complement the visual appeal and presentation of your product, reach out now.